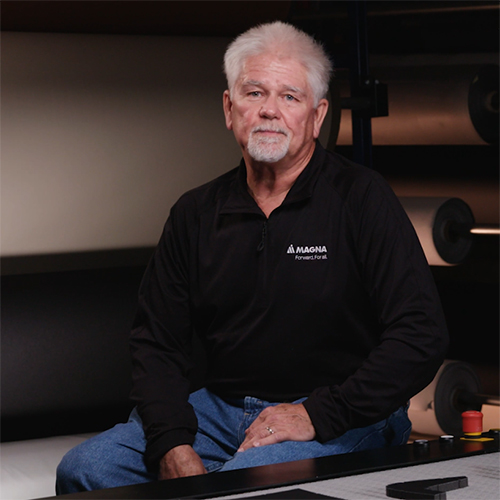

My happy place is working in pattern development in Magna’s seating innovation trim studio, where I collaborate on everything from sustainable seats to the ZG Lounger™. The studio is the perfect place for someone like me, whose day job is working on seats of the future and off-duty hours are spent sewing seats and interiors for street rods and boats.

A key part of my job is collaborating with Magna’s Innovation team on new products like the ZG Lounger™. This seat delivers a floating-in-space experience, like the zero-gravity concept from NASA. Zero-gravity seats have captured the attention of the automotive industry as consumers expect more reconfigurable seating options and increased seat comfort. These seats are inspired by the weightlessness of space, where the body assumes a neutral spine posture. The result: more flexibility to stretch out in your vehicle cabin to rest, relax and recharge.

Our seating electronics group has a studio right across the hall from where I work in our Novi, Michigan office. They do magic with the software and the wiring on our seats. The seat includes Magna SmartBridge™ Central Seat ECU with programmable software and motors that drive the seat functions, and allows the occupant to glide from drive mode, to read mode, to sleep mode with finite comfort adjustments. The functionality is enabled by our cushion tilt and leg rest mechanism. This seat cover pattern is particularly unique because of the wide range of seat motion. The seat back has an extreme recline, unique cushion tilt and leg rest extend and retract. Our team developed a creative solution to trim out the seat with best-in-class craftsmanship that supports the functionality and comfort of the seat.